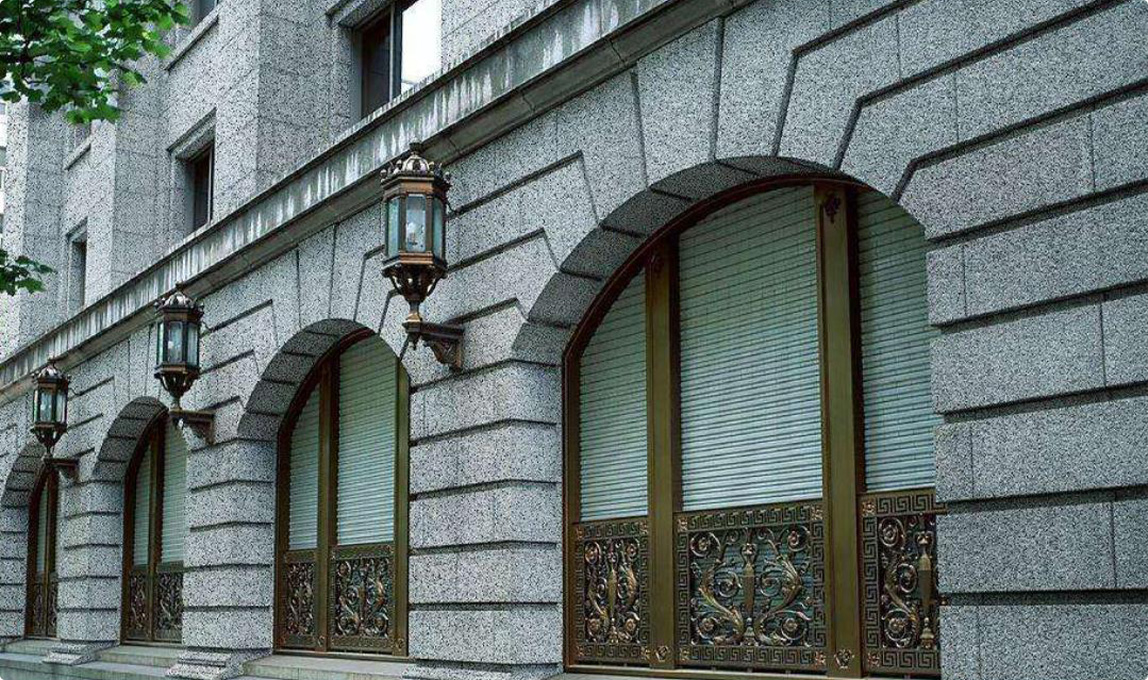

Colored Granules & Sands Applying in Industrial and

Residential Buildings

20+Years of Long-lasting Color and Weathering Performance

-

Profession

Specialized in producing ceramic colored granules and sands for 70+ years

-

Perfection

Pursuit of excellence in quality

-

Personalization

Personalized professional solutions

Roofing Granules

·CL ROCK's roofing granules is manufactured through a high-temperature inorganic process. All the pigments, binder and additive used are inorganic materials to form ceramic coating which ensure that the product is durable, stain-resistant, and chemically stable.

·Choosing opaque and high hardness as raw stone, protecting the asphalt base from sunlight.

·The surface treatment design makes the granule combine more closely with the asphalt base. Excellent hydrophobic properties will protect asphalt base from rainwater intrusion.

·Color consistency from lot to lot is tracked throughout the entire process of production and delivery: formula-production-delivery.

Specification

| Size | GCL16 12-40mesh | Appearance | Particals polygonal structure,uniform coating | Pan Residue | <40 mesh <3% |

|---|---|---|---|---|---|

| PH | 8.5-9.5 | Boiling | 5min water boiling, color no change, water basically clean | Brittleness | <1.5% |

| Alkali Resistance | 1% NaOH solution 1 week, color no change | UV Test | 500h, color no change | Dust | <0.2% |

| Moisture Content | <0.3% | Flowability | 110g <5.5 sec | Mohs Hardness | 6-7 |

| Bulk Density | 1.65±0.2g/cm3 | Specific Gravity | 2.7-2.9g/cm3 | Color Consistency | Physical check in 1 meter away, no obvious color difference compared with standard sample |

| Size | GCL16 12-40mesh |

|---|---|

| Appearance | Particals polygonal structure,uniform coating |

| Pan Residue | <40 mesh <3% |

| PH | 8.5-9.5 |

| Boiling | 5min water boiling, color no change, water basically clean |

| Brittleness | <1.5% |

| Alkali Resistance | 1% NaOH solution 1 week, color no change |

| UV Test | 500h, color no change |

| Dust | <0.2% |

| Moisture Content | <0.3% |

| Flowability | 110g <5.5 sec |

| Mohs Hardness | 6-7 |

| Bulk Density | 1.65±0.2g/cm3 |

| Specific Gravity | 2.7-2.9g/cm3 |

| Color Consistency | Physical check in 1 meter away, no obvious color difference compared with standard sample |

Roofing Copper Granules

·CL ROCK's copper roofing granules can effectively destroy the algae growing environment. They are specially designed in wet humid environmentns to solve the algae moss problem on the asphalt shingle.

·Copper roofing granules guarantees anti-algae performance for more than 10 years.

·Adding 4-10% of copper roofing granules to asphalt shingle based on wet level can achieve anti-algae effect.

·Copper granule can be designed to different color to match different shingle patterns.

·They have all the characteristics of ordinary roofing granules.

Specification

| Size | GCL16 12-40mesh | Appearance | Particals polygonal structure, uniform coating | Pan Residue | <40 mesh, <3% |

|---|---|---|---|---|---|

| PH | 8.5-9.5 | Boiling | 5min water boiling, color no change, water basically clean | Alkali Resistance | 1% NaOH solution 1 week, color no change |

| UV Test | 500h, color no change | Dust | <0.2% | Moisture Content | <0.3% |

| Flowability | 110g <5.5 sec | Mohs Hardness | 6-7 | Brittleness | <1.5% |

| Specific Gravity | 2.7-2.9g/cm3 | Bulk Density | 1.65±0.2g/cm3 | Color Consistency | Physical check in 1 meter away, no obvious color difference compared with standard sample |

| Algal Resistance | 10-15 years |

| Size | GCL16 12-40mesh |

|---|---|

| Appearance | Particals polygonal structure, uniform coating |

| Pan Residue | <40 mesh, <3% |

| PH | 8.5-9.5 |

| Boiling | 5min water boiling, color no change, water basically clean |

| Alkali Resistance | 1% NaOH solution 1 week, color no change |

| UV Test | 500h, color no change |

| Dust | <0.2% |

| Moisture Content | <0.3% |

| Flowability | 110g <5.5 sec |

| Mohs Hardness | 6-7 |

| Brittleness | <1.5% |

| Specific Gravity | 2.7-2.9g/cm3 |

| Bulk Density | 1.65±0.2g/cm3 |

| Color Consistency | Physical check in 1 meter away, no obvious color difference compared with standard sample |

| Algal Resistance | 10-15 years |

Roofing Granules

·CL ROCK's roofing granules is manufactured through a high-temperature inorganic process. All the pigments, binder and additive used are inorganic materials to form ceramic coating which ensure that the product is durable, stain-resistant, and chemically stable.

·Choosing opaque and high hardness as raw stone, protecting the resin base from sunlight.

·The surface treatment design makes the granule combine more closely with the resin base. Excellent hydrophobic properties will protect resin base from rainwater intrusion.

·Color consistency from lot to lot is tracked throughout the entire process of production and delivery: formula-production-delivery.

Specification

| Size | GCL12 16-40 mesh | Appearance | Particals polygonal structure,uniform coating | Pan Residue | <40 mesh, <3% |

|---|---|---|---|---|---|

| PH | 8.5-9.5 | Boiling | 5min water boiling, color no change, water basically clean | Brittleness | <1.5% |

| Alkali Resistance | 1% NaOH solution 1 week, color no change | UV Test | 500h, color no change | Dust | <0.2% |

| Moisture Content | <0.3% | Flowability | 110g <5.5 sec | Mohs Hardness | 6-7 |

| Specific Gravity | 2.7-2.9g/cm3 | Bulk Density | 1.65±0.2g/cm3 | Color Consistency | Physical check in 1 meter away, no obvious color difference compared with standard sample |

| Size | GCL12 16-40 mesh |

|---|---|

| Appearance | Particals polygonal structure,uniform coating |

| Pan Residue | <40 mesh, <3% |

| PH | 8.5-9.5 |

| Boiling | 5min water boiling, color no change, water basically clean |

| Brittleness | <1.5% |

| Alkali Resistance | 1% NaOH solution 1 week, color no change |

| UV Test | 500h, color no change |

| Dust | <0.2% |

| Moisture Content | <0.3% |

| Flowability | 110g <5.5 sec |

| Mohs Hardness | 6-7 |

| Specific Gravity | 2.7-2.9g/cm3 |

| Bulk Density | 1.65±0.2g/cm3 |

| Color Consistency | Physical check in 1 meter away, no obvious color difference compared with standard sample |

Round Sands

·CL ROCK's round sands has norganic ceramic interface with excellent weathering & water resistance. Also they have lower oil absorption.

·Choosing round and hard sands as raw stone which ensure the fluidity, and smoother scraping construction.

·Round sands have good abrasion resistance which will not contaminate the emulsion in coating production.

·Color consistency from lot to lot is tracked throughout the entire process of production and delivery: formula adjusting-production-delivery.

Specification

| Size | 16-30mesh and 30-40mesh | Appearance | Round particle, uniform coating | Volatile Matter | 150℃ 30min, None |

|---|---|---|---|---|---|

| Solubility | >100℃ boiling water, color no dissolving and fading | Alkali Resistance | 1% NaOH solution 1 week, color no change | Solvent Resistance | Soak in propylene glycol at room temperature for 1 week, color no change |

| Mechanical Stirring Stability |

1000RPM 15min, color no change, size no change | Resistant to Artificial Climate Aging |

600h, color no change | Moisture Content | <0.3% |

| Specific Gravity | 2.93g/cm3 | Bulk Density | 1.4±0.2g/cm3 | Color Consistency | After coating drying, comparing with standard sample, ±1.5 |

| Storage Stability | After forming coating solution, store at 50℃ 1 month, color and viscosity no change |

| Size | 16-30mesh and 30-40mesh |

|---|---|

| Appearance | Round particle, uniform coating |

| Volatile Matter | 150℃ 30min, None |

| Solubility | >100℃ boiling water, color no dissolving and fading |

| Alkali Resistance | 1% NaOH solution 1 week, color no change |

| Solvent Resistance | Soak in propylene glycol at room temperature for 1 week, color no change |

| Mechanical Stirring Stability |

1000RPM 15min, color no change, size no change |

| Resistant to Artificial Climate Aging |

600h, color no change |

| Moisture Content | <0.3% |

| Specific Gravity | 2.93g/cm3 |

| Bulk Density | 1.4±0.2g/cm3 |

| Color Consistency | After coating drying, comparing with standard sample, ±1.5 |

| Storage Stability | After forming coating solution, store at 50℃ 1 month, color and viscosity no change |

Roofing Colored Granules

·CL ROCK's roofing granules is manufactured through a high-temperature inorganic process. All the pigments, binder and additive used are inorganic materials to form ceramic coating which ensure that the product is durable, stain-resistant, and chemically stable.

·Choosing opaque and high hardness raw stone, protecting the asphalt base from sunlight.

·The surface treatment design makes the granule combine more closely with the asphalt base. Excellent hydrophobic properties will protect asphalt base from rainwater intrusion.

Specification

| Size | GCL18 10-35 mesh | Appearance | Particals polygonal structure,uniform coating | PH | 8.5-9.5 |

|---|---|---|---|---|---|

| Boiling | 5min water boiling, color no change, water basically clean | Alkali Resistance | 1% NaOH solution 1 week, color no change | UV Test | 500h, color no change |

| Dust | <0.2% | Moisture Content | <0.3% | Flowability | 110g <5.5 sec |

| Mohs Hardness | 6-7 | Specific Gravity | 2.7-2.9g/cm3 | Bulk Density | 1.65±0.2g/cm3 |

| Color Consistency | Physical check in 1 meter away, no obvious color difference compared with standard sample | Brittleness | <1.5% |

| Size | GCL18 10-35 mesh |

|---|---|

| Appearance | Particals polygonal structure,uniform coating |

| PH | 8.5-9.5 |

| Boiling | 5min water boiling, color no change, water basically clean |

| Alkali Resistance | 1% NaOH solution 1 week, color no change |

| UV Test | 500h, color no change |

| Dust | <0.2% |

| Moisture Content | <0.3% |

| Flowability | 110g <5.5 sec |

| Mohs Hardness | 6-7 |

| Specific Gravity | 2.7-2.9g/cm3 |

| Bulk Density | 1.65±0.2g/cm3 |

| Color Consistency | Physical check in 1 meter away, no obvious color difference compared with standard sample |

| Brittleness | <1.5% |

Colored Sands

·CL ROCK's colored sands has inorganic ceramic interface with excellent weathering & water resistance. Also they have lower oil absorption.

·Color consistency from lot to lot is tracked throughout the entire process of production and delivery: formula adjusting-production-delivery.

·Uniform color in the appearance. We can customize sand with different coloring power for client.

Specification

| Size | 40-80mesh and 80-120mesh | Appearance | Uniform coating | Volatile Matter | 150℃ 30min, None |

|---|---|---|---|---|---|

| Solubility | >100℃ boiling water, color no dissolving and fading | Alkali Resistance | 1% NaOH solution 1 week, color no change | Solvent Resistance | Soak in propylene glycol at room temperature for 1 week, color no change |

| Moisture Content | <0.3% | Specific Gravity | 2.93g/cm3 | Bulk Density | 1.4±0.2g/cm3 |

| Color Consistency | After coating drying, comparing with standard sample, ±1 | Mechanical Stirring Stability |

1000RPM 15min, color no change, size no change | Storage Stability | After forming coating solution, store at 50℃ 1 month, color and viscosity no change |

| Size | 40-80mesh and 80-120mesh |

|---|---|

| Appearance | Uniform coating |

| Volatile Matter | 150℃ 30min, None |

| Solubility | >100℃ boiling water, color no dissolving and fading |

| Alkali Resistance | 1% NaOH solution 1 week, color no change |

| Solvent Resistance | Soak in propylene glycol at room temperature for 1 week, color no change |

| Moisture Content | <0.3% |

| Specific Gravity | 2.93g/cm3 |

| Bulk Density | 1.4±0.2g/cm3 |

| Color Consistency | After coating drying, comparing with standard sample, ±1 |

| Mechanical Stirring Stability |

1000RPM 15min, color no change, size no change |

| Storage Stability | After forming coating solution, store at 50℃ 1 month, color and viscosity no change |

Cold Colored Sands

·Cool sands can meet and excceed Chinese JG/T 235-2014 and GB/T25261-2018 reflective standard.

·Cool colored sands has inorganic ceramic interface with excellent weathering, stain and water resistance, which ensure original & weathered solor reflective at least 3 years.

·Color consistency from lot to lot is tracked throughout the entire process of production and delivery: formula-production-delivery.

Specification

| Size | 20-40mesh 40-80mesh and 80-120mesh | Appearance | Uniform coating | Volatile Matter | 150℃ 30min, None |

|---|---|---|---|---|---|

| Solubility | >100℃ boiling water, color no dissolving and fading | Alkali Resistance | 1% NaOH solution 1 week, color no change | Solvent Resistance | Soak in propylene glycol at room temperature for 1 week, color no change |

| Resistant to Artificial Climate Aging |

600h, color no change | Moisture Content | <0.3% | Specific Gravity | 2.93g/cm3 |

| Bulk Density | 1.4±0.2g/cm3 | Color Consistency | After coating drying, comparing with standard sample, ±1 | Mechanical Stirring Stability |

1000RPM 15min, color no change, size no change |

| Storage Stability | After forming coating solution, store at 50℃ 1 month, color and viscosity no change |

| Size | 20-40mesh 40-80mesh and 80-120mesh |

|---|---|

| Appearance | Uniform coating |

| Volatile Matter | 150℃ 30min, None |

| Solubility | >100℃ boiling water, color no dissolving and fading |

| Alkali Resistance | 1% NaOH solution 1 week, color no change |

| Solvent Resistance | Soak in propylene glycol at room temperature for 1 week, color no change |

| Resistant to Artificial Climate Aging |

600h, color no change |

| Moisture Content | <0.3% |

| Specific Gravity | 2.93g/cm3 |

| Bulk Density | 1.4±0.2g/cm3 |

| Color Consistency | After coating drying, comparing with standard sample, ±1 |

| Mechanical Stirring Stability |

1000RPM 15min, color no change, size no change |

| Storage Stability | After forming coating solution, store at 50℃ 1 month, color and viscosity no change |

Value-added

Services

-

C

Provide complete

customized color

matching service -

S

Meet customer specific

requirements and

industry standards -

W

Provide professional technical

support for pre-sale, sale and

after-sale tracking